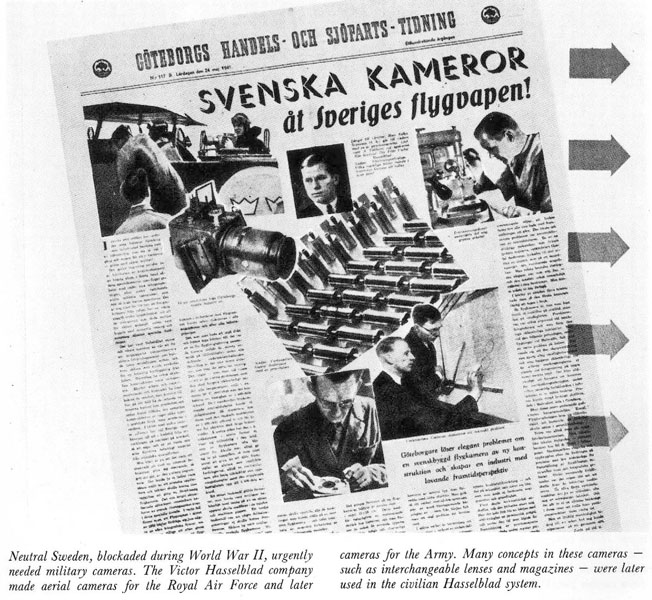

Ross Military Cameras

By Charlie Chernoff

Part Two - HK 7 Hand Camera

The first manufactured Ross aerial camera was the Flyghandkamera HK 7. Design and prototyping began in 1940

and the first working specimen was ready early in 1941. At this point staffing was increased to twenty and a

move was made from makeshift quarters in an empty shed to what became a factory building.

More staff was added later and the Ross factory went on to produce and deliver 240 HK 7 aerial cameras.

Additional camera designs were perfected and put into production. These will be dealt with later.

The camera bodies were built in the Ross (Hasselblad) shop but Victor and employees did not attempt to

fabricate lenses. Victor’s Ross shop did make the shutters.

Lenses all came from Germany, from Zeiss and Schneider and Meyer. No one has found any factory documentation

that refers to procedures detailing the importation of lenses from Germany to Sweden. Sweden, during the war

period, was trying desperately to stay neutral so they were willing to cooperate and trade with the German

government on a low-level basis. Germany desperately needed iron ore, wood and ball bearings from the SAAB

factory. Sweden needed lenses among other things but most of all Sweden needed to be left alone. The Allies

must have been aware of the trade activity but were willing to ignore the issue. Most likely trade

arrangements were made at the government to government level. Incidentally Sweden also traded ball bearings

to Great Britain for items not manufactured in Sweden.

|

As promised Victor Hasselblad did improve on the German HK 12.5cm/7x9 aerial camera. Victor used

behind-the-lens shutters to overcome image distortion at faster airplane speeds and he used interchangeable

lenses so that different focal lengths could be attached as flight conditions of route and altitude demanded.

He used interchangeable backs and he introduced intervalometers for sequence photography as well as date and

time stamping, in later cameras.

In the specification details that follow for the several Ross Aerial cameras you will occasionally

encounter the following entry, [Information reguested].

This entry alerts the reader to the fact that the author does not have any information regarding a

particular feature and is asking the readership to contribute detail if they have information from

literature or from studying an owned specimen.

Body

Cast aluminum body with removable plates on both sides. Medium to dark gray color with black wood handles.

Two small aluminum identification plates are screwed onto the top of the camera on either side of the speed

setting knob.

Right plate has the following engraved on it "TILLVERKAD AV ROSS Aktiebolag, Göteborg" (Made by Ross Co.,

Gothenburg).

The left one has the following engraved on it, "HK 7" and below that the camera serial number.

Dimensions and weight

Length: 31 cm.

Width: 26 cm, including handles - 13.5 cm, body only.

Height: 17.6 cm.

Weight: 4.8 kg. with 13.5 cm lens attached.

Back

Removable rear cover that slides off the cast aluminum body with no provision for a dark slide.

Film Flattener

Spring loaded flat plate that is lifted free during film advance.

Photo Format

Picture size is 7 x 9 cm.

Film

80 mm wide double perforated roll film with 70 mm available for exposure.

Film Advance

By a pivoted lever that is mounted in a flat turret atop the camera. The lever is pushed forward by the left

thumb.

Power supply

None.

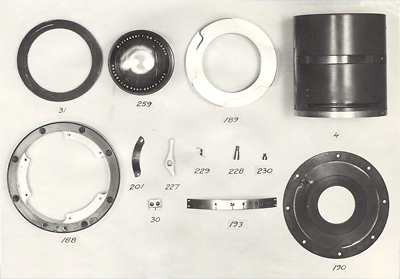

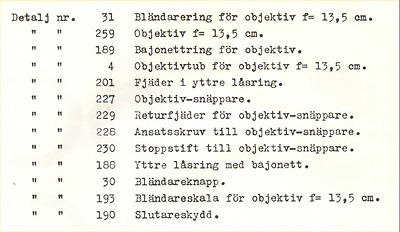

Lens Mount

Unique, robust three lobed bayonet mount with an outer spring loaded catch of substantial size. Lobes are of

unequal size, one being narrower than the other two so that the lens fits in only one position.

Lenses

Interchangeable lenses. Lenses are not anti-reflection coated.

Standard lens is a 13.5 cm. f/2.8 Zeiss Biotessar,

Telephoto lens 24.0 cm. f/4.5 Schneider Xenar,

Telephoto lens 25.0 cm. f/5.5 Meyer Tele-megor.

Aperture Values

Biotessar lens 2.8, [Information requested]

Xenar Lens 4.5, 5.6, 8, 11, 16

Tele-megor lens 5.5, 8, 11, 16, 22

Focus Control

Fixed focus at infinity.

Metering

Light value reading with auxiliary hand meter (not supplied).

Shutter

Behind-the-lens shutter.

Shutter has four leaves on cameras examined.

Throat diameter is 40 mm.

Shutter Speeds

1/150, 1/250, 1/400

Flash Capabilities

Not synchronized for flash.

Viewfinder

Folding frame finder for two focal lengths.

The inside frame for a telephoto lens will work with both the 24 cm and 25 cm focal length lenses. Outside

frame for 13.5 cm lens.

Exposure Release

Pivoted finger release with right index finger.

Accessories

Instruction book in Swedish.

Slide-in filters slip into lens barrel slot in front of lens (filters can be identified even when they are in

the barrel slot - the red filter has a large red dot on the top of the filter frame; the orange filter has a

large yellow dot on the top).

Wood carrying case.

Innovations

Until this time cameras with similar and larger photo format traditionally used focal plane shutters. Use of a

behind-the–lens shutter made mechanics much simpler in the body of the camera and allowed faster airplane fly

over speeds with less image distortion than with focal plane shuttered cameras.

Other Features

Folding wind crank on camera bottom to complete winding on unfinished roll or trailing tail of finished roll.

Turn clockwise.

There is an off white (may have been white before weathering in the sun) plate, 5.4 x 7.4 cm, screwed onto the

rear cover. Memo items can be recorded on this plate and erased when no longer relevant and the plate can then

be re-used. For instance message might say; “Kodak XX film, 400 ASA”.

The camera is incredibly well made with great attention to detail even though war was all around and a need

for urgency was being expressed by the Royal Swedish Air Force. We need only look at the machining of the

bayonet mount, the lens cap, and the filters. These are all components that can be examined with no need for

disassembly. The three lobed bayonet mount is machined to such perfection that one must look closely to see

the line where it meets the protective lens barrel. The lens cap is held in place by three latches that all

fit a machined recess inside and at the front of the protective barrel. Depression of a single, outer slide

withdraws all three spring loaded latches making lens cap removal a simple task even with gloves on. The inner

plate holding the spring assembly in place has six screws where three might have done the job albeit not as

neatly or securely.

Filters slide into a slot cut into the top of the lens barrel. But they don’t just slide in and depend on gravity to hold them securely. On either side of the aluminum filter frame there are spring-loaded ball bearings. These bearings act as secure detents because as filters enter the barrel the balls are depressed and then they click outwards into depressions drilled into the inside of the protective barrel wall. The filter frame is symmetrical front to back so filters cannot be inserted backwards since back and front are identical. A very neat, very secure, very unobtrusive, very elegant design and execution.

The substantial size and ergonomic placement of all controls and shutter release allow adjustment and use of the camera even with bulky, awkward gloves on. See lower photo on page 31 in the book Hasselblad. Twenty years later Victor and his crew were again putting oversize “butterfly wing” tabs on lenses and oversized magazine latches on Hasselblad motorized cameras for use by gloved NASA astronauts.

The rear cover fits snugly over the cast aluminum frame so it is reasonable to assume that it was hand fitted to a particular camera. To assure that the fitted cover was re-attached to the proper camera body, the serial number of the camera was stamped into the top of the white memo plate described above. To make sure the cover was replaced correct side up there is a red dot on the cover that must be aligned with a red dot on the camera body.

Years later this attention to detail was carried over to commercially manufactured cameras. Often the magazine (back) insert had to be hand fitted to fit light tight. To assure that inserts did not get put on an incorrect back the serial number of the back was stamped on the insert. It is interesting that this practice began at the 1600F cameras of1950 which have two alpha letters preceding the serial number. The earlier four numeral (Nul) 1600F magazine inserts do not have an identifying serial number stamped on them.

Lenses were also identified with the serial number of the camera. On the HK 7 the serial number of the camera appears on the f/stop plate, to the right of the engraved f/stop values.

We have more than a wartime utility camera, we have a precision instrument.

Production Span

1941 - 1943.

Number Produced

240.

Serial Numbers

1 through 240.

Comments

This Ross Aerial camera launched the career of Victor Hasselblad of Hasselblad fame as a quality and

innovative camera maker whose major concerns were to design and build the best commercial camera product a

photographer could buy. Profit margin was of secondary importance and, in fact, the Hasselblad Company made

no profit and probably did not break even most years from 1948 through 1957.

The Ross name was changed to Hasselblad when Victor contemplated marketing on an international scale and found

that the Ross name had already been taken in Great Britain, and after he had acquired controlling interest of

his grandfather’s Hasselblad Company from his siblings.

The HK 7 camera had the beginning elements of features that would be incorporated into the commercial

cameras. For example: interchangeable lenses were common to Ross military and Hasselblad commercial

cameras.

It is interesting that the first commercial cameras had complicated metal focal plane shutters as

opposed to simpler behind-the-lens shutters of the military cameras. This probably was because Victor wanted

a camera with a fast shutter speed to capture sharp pictures of moving birds. The first prototype commercial

camera had a metal focal plane shutter that was intended to have a top speed of 1/2000 seconds. This must have

not been achievable with materials and design available so the next two working prototypes had metal focal

plane shutters with a top speed of 1/1600 second just like the commercial 1600F.

The top speed of 1/400 seconds on the HK 7 may have been a compromise to ensure that the shutter blades were

not subject to undue stress and would thus be more reliable and last longer. Follow on cameras had a top speed

of only 1/300 second. Speeds of 1/500 were more common in commercial shutters.

Provisional HK7 Spare Parts Catalogue.

Cover and sample of content.

Ross Aktiebolag, Göteborg |  |

|

Copyright 2007, 2008 - Charlie Chernoff. All rights reserved.

All material on this site is protected by law. Unauthorized use is prohibited.

- Hasselblad Historical -